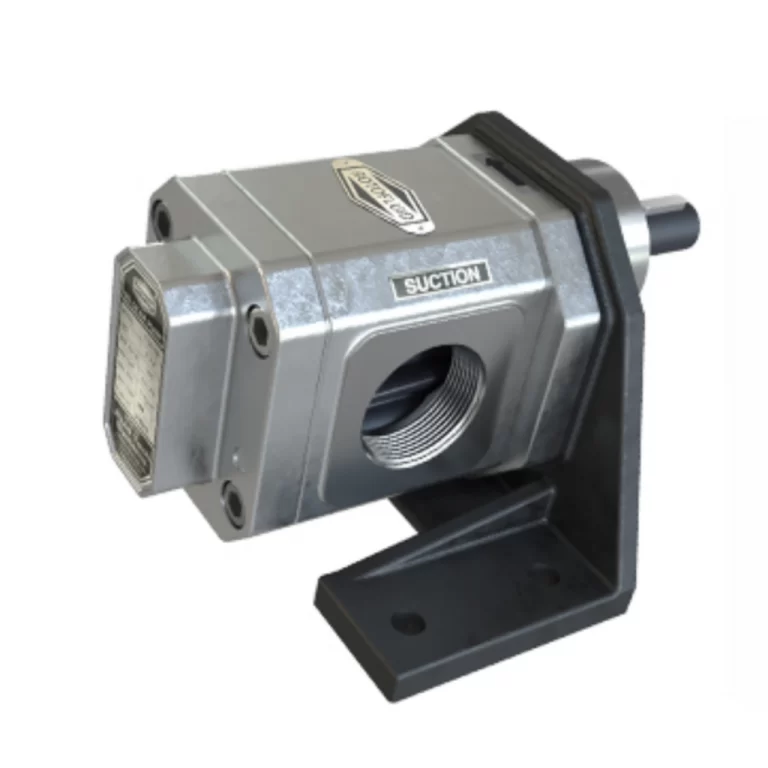

Fuel Injection Internal Gear Pump

LDO Pump Manufacturer & Dealer

Transmission Chain Centre is the Leader in Manufacturing and Supply of Fuel Injection Pump Internal Gear Pump, Internal Gear Pump and Internal gear pump.

Transmission Chain centre presents the Fuel Injection Pump Internal Gear Pump. The pump is made up of graded cast iron. The Internal Gear Pump is one of the highest selling product in India and also this LDO Pump is manufactured and exported to many countries due to its durability and long life.

We at Transmission Chain Centre offer the “ROTOFLUID” brand internal gear pump also known as LDO pump as it is very good for handling fuels like LDO, FO, Diesel , HSD and LSHS.

The Fuel injection Internal Gear Pump is known by many names like Boiler Firing Gear Pump, FIG Pump, LDO Gear Pump, HSD Gear Pump, Burner Firing Gear Pump or commonly called as Diesel Filling Gear Pump which gives good control while transfer of highly Inflammable liquids.

The fuel pressuring type positive displacement internal gear pump which is made from graded cast iron, Having nitrated gear, shafted rotor to give superior performance and as it has a high pressure tolerance it increases the longevity of the product.

Model “FIG” is flange mounted. These pumps are self priming type produces maximum, vacuum determined by the cavity between the gear teeth. These pumps modified profile teeth cutting to give accurate capacity with in the pressure range.

These pumps are capable to run liquid up to 500 CST viscosity and up to temperature 200ºc. The sealing is done with mechanical seal to ensure zero leakage.

The suction and delivery connections are available in 3/8″,1/2″,3/4″and 1″ size. Model “FIG” pump come in a capacity Range of 60 LPH to 6000 LPH with operating pressure up to 35 kg/cm², yet for continuous duty maximum recommended pressure is 30kg/cm². These pumps can also be used at 2800 RPM. The capacity will have almost double of normal duty condition.

These pump can be run both clock and anti clock direction as per requirement.

Download documents

Technical Specification

Model

Capacity in LPH at 1440 RPM

Suction & Delivery Size

Motor HP

3 kg/cm²

30 kg/cm²

FIG-S6

60

3/8" x 3/8"

0.25

1.00

FIG-S9

90

3/8" x 3/8"

0.25

1.00

FIG-S12

120

3/8" x 3/8"

0.25

1.00

FIG-A15

150

1/2" x 1/2"

0.25

1.50

FIG-A30

300

1/2" x 1/2"

0.25

1.50

FIG-A45

450

1/2" x 1/2"

0.25

2.00

FIG-A60

600

1/2" x 1/2"

0.25

2.00

FIG-B100

1000

3/4" x 3/4"

0.75

3.00

FIG-B150

1500

3/4" x 3/4"

0.75

3.00

FIG-B200

2000

3/4" x 3/4"

0.75

5.00

FIG-B250

2500

3/4" x 3/4"

0.75

5.00

FIG-C300

3000

1" x 1"

1.50

7.50

FIG-C450

4500

1" x 1"

1.50

10.0

FIG-C600

6000

1" x 1"

1.50

15.0

| Model | Capacity in LPH at 1440 RPM | Suction & Delivery Size | Motor HP | |

| 3 kg/cm² | 30 kg/cm² | |||

| FIG-S6 | 60 | 3/8" x 3/8" | 0.25 | 1.00 |

| FIG-S9 | 90 | 3/8" x 3/8" | 0.25 | 1.00 |

| FIG-S12 | 120 | 3/8" x 3/8" | 0.25 | 1.00 |

| FIG-A15 | 150 | 1/2" x 1/2" | 0.25 | 1.50 |

| FIG-A30 | 300 | 1/2" x 1/2" | 0.25 | 1.50 |

| FIG-A45 | 450 | 1/2" x 1/2" | 0.25 | 2.00 |

| FIG-A60 | 600 | 1/2" x 1/2" | 0.25 | 2.00 |

| FIG-B100 | 1000 | 3/4" x 3/4" | 0.75 | 3.00 |

| FIG-B150 | 1500 | 3/4" x 3/4" | 0.75 | 3.00 |

| FIG-B200 | 2000 | 3/4" x 3/4" | 0.75 | 5.00 |

| FIG-B250 | 2500 | 3/4" x 3/4" | 0.75 | 5.00 |

| FIG-C300 | 3000 | 1" x 1" | 1.50 | 7.50 |

| FIG-C450 | 4500 | 1" x 1" | 1.50 | 10.0 |

| FIG-C600 | 6000 | 1" x 1" | 1.50 | 15.0 |

Additional Information

Features

- Higher suction lift.

- Self priming pump and Capacity to create vacuum up to 600/650 mm hg

- Flange and Foot mounting option.

- Optionally available in investment casting.

- Zero leakage mechanical seal.

- Maximum temperature up to 200º c.

- Continues duty pump.

- Internal lubrication systems.

- Available with or without built-in pressure relief valve and external by pass.

- Pressure regulator, progressively adjustable.

Application

- Highly used in fuel injection Burners, Boilers, Furnaces.

- Booster application in diesel locomotive.

- Force feed lubrication.

- Eventually with separate pressure regulating valves.

- For gas oil, medium, heavy and very heavy oil.

- Filter pumping.

- Pumps for PHF units.

- Pump for hydraulic oil.

- Pump suitable for LDO, FO, HSD and LSHS.